Some of the biggest brands in electronics and furniture have worked together to discover how 3D printing can disrupt the way they make and use spare parts.

As part of the Ellen MacArthur Foundation’s Circular EconomyCircular EconomyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature. 100 platform, HP, Teleplan, IKEA, Philips, and iFixit embarked on a year-long collaborative project (Co.Project) exploring new applications of 3D printing technology.

The project focused specifically on spare parts. Today, it can be difficult for brands and manufacturers to know when and how to deal with spare parts. As products change and are redesigned, the equipment used to make the parts changes too. So a business can’t continue to make spare parts for products produced years ago. One option could be to produce spare parts in bulk, but there’s no way to predict future need, to know which parts to make, how many and how long they will last. What’s more, a brand like IKEA has around 12,000 different types of products, so this approach would require huge amounts of storage space.

How does this relate to a circular economy? If a customer can’t get spare parts, even a small malfunction can mean a product is destined for the dump. In order to keep more products in use for longer, access to spares is vital, as iFixit’s Kyle Wiens explains, “RepairRepairOperation by which a faulty or broken product or component is returned back to a usable state to fulfil its intended use. represents 3% of employment, but growth is often stymied by the logistical complexities of planning for and distributing service parts. On-demand production of spares would change the game.”

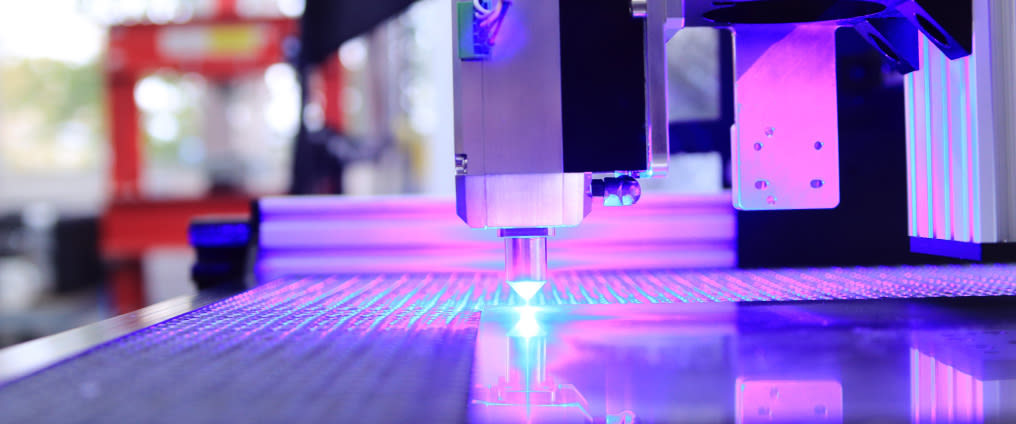

This is where 3D printing comes in. Rather than keeping an inventory of parts, a business can keep an endless database of digital files. Because they’re made using a 3D printer, it doesn’t cost anything to change between an infinite variety of designs, and you could even use a scan or your imagination to design a part you didn��’t predict you would need. This method could also take the guesswork out of manufacturing. Rather than making thousands of parts at once, individual items could be printed only when they’re needed.

The CE100 collaborative project, initiated by HP and Teleplan, sought to explore this hypothesis. It took a two-pronged approach that tapped into the design and innovation expertise of both established businesses and individual inventors.

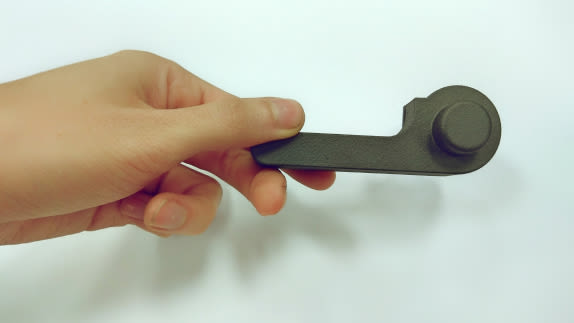

A 3D printed lever for a Bugaboo stroller.

A 3D printed part for a Bugaboo stroller.

Firstly, the two businesses worked together closely to see how 3D printing would work for a specific part. The product was an HP OfficeJet printer, an item for which Teleplan offer aftersales service, supporting the ongoing maintenance and repair of the product. Clearly, their business would be further strengthened through the easy ongoing support of electronic products, as Xavier Hubert explains:

“Product support specialists face real parts supply chain challenges every day: forecast commitments, minimum order quantities, long lead times, freight costs, critical inventory balancing and positioning, and excess and obsolete inventory. Last-time-buy decisions, in particular, are driving huge storage costs and result either in excess or missed opportunities on future repairs. This is a bet no one ever wins, exposing both the planet and the bottom line. On-demand 3D printing could potentially solve all this.”

HP tackled four different spare parts, manufacturing them using the MultiJet Fusion 3D printer. At this experimental stage, the results were mixed, and the 3D printed parts varied in texture, colour, and accuracy. Teleplan conducts warranty repairs, so consistency and reliability are important. The team realised that when products are designed and produced with one technology, it can be difficult to simply introduce 3D printing technology within the manufacturers’ support and repair strategy. As a result, the team decided that the parts from the experiment wouldn’t be practical for their business.

HP and Teleplan call this “engineering lock-in”, and it reveals an important point that’s consistent with other circular economy innovation: technology alone won’t be enough. Bolting a technological fix on to a product designed for established ‘linear’ production and distribution will have limited impact.

For the second part of the Co.Project, the group opened up to a global pool of knowledge and experience in design and 3D printing. Working with iFixit, they launched the Dare to Repair contest, which challenged people to invent and design spare parts for real-world problems with everyday products. The winning entries would be printed by HP. Free from the constraints of giant supply chains and processes, would domestic makers put 3D printing to use?

Some of the best entries included a spacer for a stuck drawer and series of replacement levers and buttons for Bugaboo stroller.

Electrical engineer Anthony Kouttron designed a tiny cover for a camera battery on an expensive SLR camera. It proved to be the winning entry, partly down to the way Anthony meticulously documented the design and prototyping process.

He explains how the part in question is prone to breaking on this specific model of camera, and it can render the $600 camera useless. Anthony’s work also demonstrates how designers can account for inaccuracies in the 3D printing process at the design phase — by tweaking the size, shape, and material of the item — making the printed spare part more reliable. It’s this constant customisation and adaptability that makes 3D printing so useful, but perhaps is also the reason 3D printing as a process doesn’t slot nicely into today’s supply chains, which are geared towards standardisation and efficiency.

The winning entry in the Dare to Repair contest might look simple, but it could keep a camera — itself worth hundreds of dollars — in use for much longer.

The project has inspired further research for the brands involved. For this first experiment, the team at HP restricted itself to one 3D printing material and limited production runs, but it’s likely that further fine tuning or part finishing could give better results. In a separate investigation, also at HP, 3D printing is being designed and used in an original product. By factoring in 3D production at the start, it’s fair to expect that the printed spares would better integrate with the overall product.

“If considered in original product design, we believe 3D printing has the potential to overcome many pitfalls in current sourcing of spare parts”, says John Ortiz, who led the project from HP. Following the project, he has even stronger faith that 3D printing will change the way we make and use products, and is an important part of the circular economy transition. “With this technology, we can address the challenges of long supply lead times for repair parts, minimum order quantities, the costs associated with transportation, logistics, and inventory holding, and ending production runs on spares.

“With the potential to change the economics of spare part support, we can also change the design incentives for product manufacturers. With our internal projects and a new collaboration we are commencing with Catalonia Industry clusters, we will have the ability to better understand the economic incentives for product design with 3D printing in production, and how it can help other industries keep materials and products in use for a longer period of time, at their greatest state of value”.

By getting hands-on and fabricating functional prototypes, this partnership has clarified the obstacles and opportunities of on-demand spare parts.