Learnings from an aspirational paddle board business

Moving a business towards a circular economycircular economyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature. model can throw up all sorts of challenges for those entrenched in supply chains built on linear economics. Red Paddle Co, a company that specialises in inflatable paddle boards, is one such business turning innovation efforts towards ensuring its products can soon be made for a circular economy.

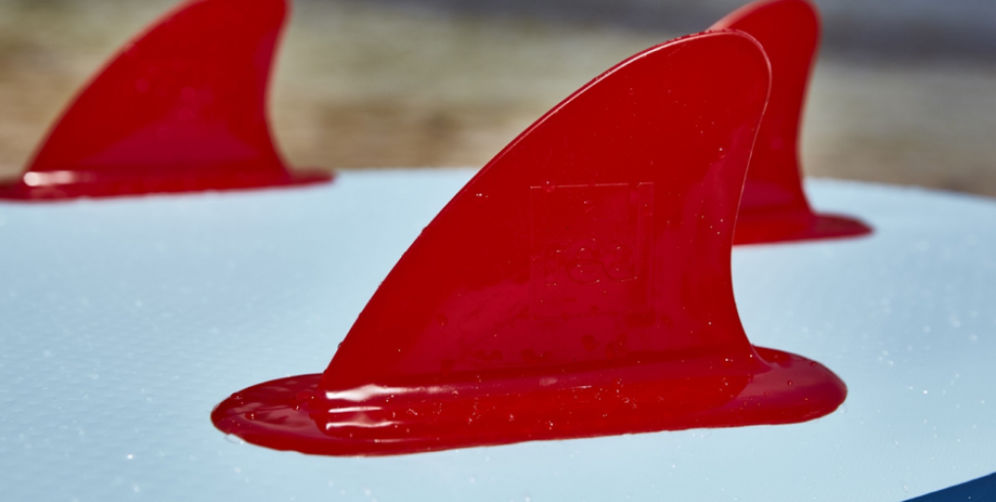

Image: Red Paddle Co

Since 2008, Red Paddle Co has focused on making inflatable paddle boards that perform as well as, if not better than, hard boards. Having refined the paddle board design for performance, Red Paddle Co’s Head of Design, Phil Hawthorne, is focusing on his company’s transition to a circular economy business model.

“Since 2015 we have been slowly making the shift towards a more circular model,” Phil said. “We’re not there yet and I don’t think we will be there in the immediate future. However, we’ve taken some big steps in the right direction.”

Designing out waste and pollution

In a circular economy, waste and pollution are designed out of product life cycles entirely. If we accept that waste and pollution are the results of decisions made at the design stage of a product, it follows that we can choose to view them as design flaws, and we can innovate our way to a circular economy. This means designing for circular economy from the outset.

Phil said: “We are going through a pretty rapid growth phase and because of this, innovation and product development is at the top of the agenda, allowing us to consider the circular economy right at the ideation phase. You need to closely scrutinise every stage of the design and manufacturing process to ensure your product stays in use, and doesn’t end up as waste.”

Design innovation may be the key, but most products exist within extensive value chains with multiple different players involved. Therefore, as well as being an innovation challenge, the circular economy requires collaboration and shared ambition. This can create a barrier for businesses trying to build circular economy business models.

Phil said: “We are really fortunate to be able to directly educate our suppliers, however our second-tier suppliers don’t always understand what we are trying to do and allocate little or no resource to it as they cannot see the direct gain immediately.

“I’ve had some pretty heated discussions about which materials we can use for certain products and components when driving our circular economy message, so improving their knowledge is something we are always working on.”

But what if suppliers simply can’t provide materials with the properties a product requires, while still fitting into a circular economy? In the case of inflatable paddle boards, the main material used is a reinforced laminate, where layers of different materials are fused together. This material is not currently recyclable.

“The materials we want to use are really expensive or they don’t exist yet,” Phil said. “For a couple of upcoming projects, we are actually introducing suppliers to one another so they can pool orders to get the price point we need for emergent materials.

“We have developed several materials with our suppliers, some of which have now been successfully applied and others have not. As these and other materials are developed, the cost will reduce and the applications will become more accessible. There are several materials I am waiting for and I always watch future developments closely.”

Image: Red Paddle Co

Sometimes, an easy starting place for redesigning products for circular economy is with their packaging. This can involve eliminating unnecessary or problematic materials from packaging, innovating so that any crucial packaging is compatible in a circular economy, and circulating materials so they never become waste.

At Red Paddle Co, their first step on the road to circular economy was with their packaging.

Phil said: “Our first project was to remove glue from our packaging and instead utilise mechanical fastenings. The manufacturing process is a little more time consuming and therefore more expensive than the original packaging, but we feel it’s a worthwhile investment and one we will continue with.

“As a second iteration, we decided to try and make our packaging completely compostable by looking into bio-based packaging, soy-based inks and corn starch polyethylene replacements. Some of these changes were simply too expensive at the time but the changes that we have made have pushed us ever closer to our goal of 100% compostable packaging.”

Built to last

Alongside designing out waste and pollution, another key principle of the circular economy is to keep products and materials in use. Red Paddle Co is working to make their products as durable and repairable as possible.

“We are so confident in our product we now offer a 5 year warranty on all new boards as standard,” Phil said. “We build them to last.

“However, faults finding their way through the system are inevitable in manufacturing, and things do happen when out and about during a paddle. As such, we include a repairrepairOperation by which a faulty or broken product or component is returned back to a usable state to fulfil its intended use. kit with all of our board packages. We are also quite fortunate that there are a lot of RIB [rigid-hulled inflatable boat] and boat repair services around that can also help with any more serious incidents, so that existing ecosystem can offer extra support.

“We don’t provide a return and repair service — yet. However, we have focused on customer service, with 24-hour support and advice, and can provide spares for repair for almost all circumstances.

“One of our first products was the Titan pump. At the time we didn’t have the knowledge we do now, but we made the pump as repairable as possible. To date, the level of repairabilityrepairabilityThe ease with which a product or component can be repaired. of our products improves with every launch, and now every single product we produce is serviceable in some way or another. A major advantage of product serviceability is that it allows the customer to extend the life of their product indefinitely and offsets disposal.”

Image: Red Paddle Co

As well as designing for durabilitydurabilityThe ability of a product, component or material to remain functional and relevant when used as intended., companies must consider what happens to their products at the end of their use. This is a sticking point for many companies whose products may not be easily disassembled or contain materials that can not be recycled, reused or composted.

Phil said: “We always ask ‘what happens next with the material?’, and we’re currently working with a few ideas relating to material recapture and repurposing current products. There are also a couple of ideas and research projects for complete recovery of the material for future boards, however at this stage the funding would be a pretty major barrier to entry.”

Shifting to a circular economy is no easy task, but as more companies begin their transition and more start-ups launch with circular economy in mind, the easier the transition will become — until eventually the momentum is unstoppable.