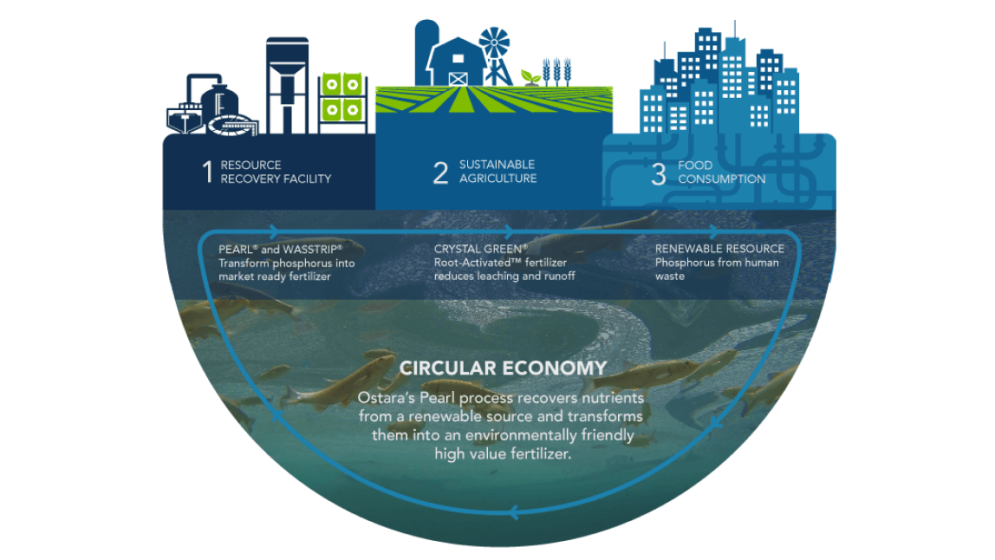

The Need - the current linear approach to agriculture removes important nutrients from the soil, passes them through a value chain and discards them in a way that can lead to unproductive soil and negative environmental impacts. There are finite reserves of many key resources and in some cases, such as phosphorus, there is no synthetic alternative.

The Solution - Ostara has developed technology that can be incorporated into treatment plants allowing phosphorus and other nutrients to be recovered from industrial and municipal wastewater streams. The product can then be marketed, distributed and sold to blenders, growers and farmers as a pure and effective fertiliser, produced from resources that would otherwise be wasted.

What makes it particularly smart - the process reduces the build up of phosphorus and other nutrients, called struvite, on pumps and pipework. This addresses a costly operational issue, common in treatment plants, using biological phosphorus removal. The end product called ‘Crystal Green’ is not water soluble; it releases nutrients to plants in response to growing roots, which means there is a significant reduction in leaching and runoff from crops, as the plants are more efficiently nourished.

The Result - wastewater plants have an additional revenue stream, increased efficiency and lower operational costs; nutrient loading to waterways is reduced; fertiliser efficiency is improved for farmers and there is a reduced carbon intensity.

Healthy soils are the foundation of the bio-economy

A balanced supply of nutrients is essential for healthy plant growth. In the absence of human activities, natural processes such as biodegradation as well as symbiotic relationships with other species in the local ecosystem provide sufficient nutrition for the plant life cycle, albeit in an environment of healthy competition.

Human agricultural activities affect this natural nutrient balance. When crops are harvested nutrients are removed from the soil, as they are contained in the grains, vegetables, fruits, fodder, timber and other useful biomass that is taken away. All of these are important materials for feeding people and supporting the economy, but the process removes essential elements required for future generations of plant growth.

In the past, less mechanised, more local forms of agriculture returned nutrients in the form of agricultural by-products, the spreading of human and animal waste and intercropping. As farming methods have become more industrialised and mono-cultured, the effect has been to increase yields, leading to improved profit margins, lower food costs and a reduction in hunger. However sustaining yields means soil health and fertility is now provided by artificial chemicals rather than natural means. These chemical alternatives can be expensive, relying on resources that are increasingly hard to recover and involve carbon intensive production processes.Furthermore, current chemical fertiliser utilisation is quite ineffective. A report released in 2015 estimated that only 5% of the fertilisers applied, contribute to parts of plants that we eat.

Meanwhile at the other end…

At the other end of the chain is the wastewater treatment plant. Nutrients, by now dissolved in municipal and industrial wastewater, are captured in expensive mechanical, biological and chemical processes. This ensures that water is safe to be discharged into the wider water system, according to local environmental regulations.

Spurred on by increasingly stringent regulation, Ostara Nutrient Recovery Technologies, a Vancouver-based company, has taken a more systemic approach to managing nutrient flows. The result is an innovative wastewater add-on process and a pure fertiliser product that creates revenue for the business.

The location of phosphorus determines whether it is a liability or an asset. When deposited as the mineral phosphate struvite on pipe and pump work in treatment plants, or if discharged in elevated concentrations to freshwater sources, phosphorus can be both economically and environmentally costly. However in the form of a fertiliser product contributing to high yields and healthy plants, phosphorus can be an attractive revenue stream.

Recognising this dichotomy, Ostara developed a nutrient recovery approach called the ‘Pearl® Nutrient Recovery Process’, easily integrated into biological-based wastewater plants, reducing problematic phosphorus and turning it into a highly effective plant fertiliser called ‘Crystal Green®’.

How it works

Ostara’s solution is a two-stage process that can be applied to a particular configuration of sewage treatment (known as Enhanced Biological Phosphorus Removal), a treatment method in which biological processes are selectively enriched with specific phosphate-absorbing bacteria. Having accumulated large quantities of polyphosphate within their cells, the bacteria re-release the phosphorus into a soluble form and then placed in an anaerobic digester. The result is a concentrated, phosphorus-rich stream that is fed through Ostara’s ‘Pearl Process’, where phosphate crystallises into pure fertiliser granules.

The process is complemented by a second installation (called WASSTRIP) that diverts wastewater upstream of the anaerobic digester, significantly reducing struvite build up in critical plant components as well as maximising phosphate recovery by the Pearl process. In the further material section at the end of this article, a video link provides a visual explanation of how these two processes are integrated into a typical treatment works.

The technology can be applied in a number of reactor sizes according to the population served, ranging from 50,000 to 1 million populations. Pearl and WASSTRIP can either be retrofitted into existing facilities or incorporated into the design of brand new plants.

Win-win-win

Ostara’s nutrient recovery system provides financial benefits to farmers, utility companies and shareholders, while at the same time satisfying regulators and conservation groups. Ostara also avoids negative impacts to the local aquatic environment, contributes to positive urban-rural connectivity and reduces carbon intensity associated with agriculture.

Financially, farmers are better off because they do not need to use so much fertiliser. Crystal Green is known as a ‘continuous release, Root-Activated™’ product. This means that instead of acting through water solubility, the fertiliser granules hold back until signalled via a chemical message from the plant root to release nutrients into the soil. Unlike conventional fertiliser application where up to 75% can be washed away, Crystal Green fertiliser is transferred much more effectively to the plant, avoiding excessive nutrients which could cause eutrophication in nearby bodies of water, whilst also remaining available to the plants for a much longer proportion of the growing season. Utility companies are financially better off, as an additional revenue stream has been created through fertiliser sales. Besides these extra profits, their operational costs are also lowered as less chemicals are needed to manage struvite deposits, and there is a 10-20% reduction in leftover sludge requiring disposal.

In global terms, greenhouse gas emissions are reduced as each tonne of Crystal Green eliminates 10 tonnes of CO2e compared to equivalent standard fertilisers. If scaled up, this could be an important contribution to reducing the carbon intensity of the agricultural sector, which is estimated to be responsible for 17% of emissions.

The basic template for an urban sewage system has remained unchanged since the 1870s, when the world’s first underground network was installed in London. While Bazalgette’s system was very effective at cleaning up the ‘Great Stink’, its design was extremely 'linear' in that it took nutrients from where they are useful (farms), discarding them to a place where they are problematic (waterways). Technology like Ostara’s should be the next evolution of Bazalgette’s ideas, ensuring that the next generation of more ‘circular’ sewage systems not only protect public health but also close nutrient loops back to farmland.