name:

Coca-Cola Enterprises

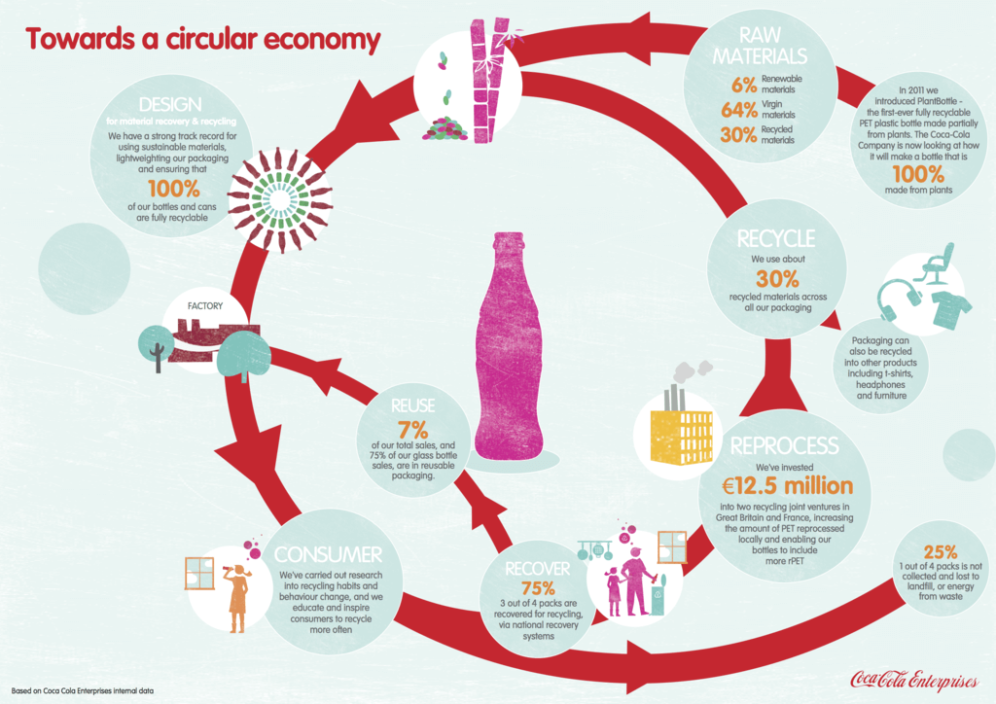

Coca Cola Enterprises is committed to maximising the usage and value of the plastics used in bottle production. To help achieve this ambition Coca Cola invested in Continuum Recycling; a plastics reprocessing facility for collecting and reprocessing plastics as a joint venture with ECO Plastics.

Through interventions at each stage of the packaging chain (materials, design, disposal, recovery and recycling), CCE is committed to maximising the usage and value of the plastics used in bottle production. It has several commitments in this area including a target of reducing 25% of material used by 2020, to use more renewable content, such as plant-based PET, in packaging, and to improve the overall recyclabilityrecyclabilityThe ease with which a material can be recycled in practice and at scale. of their packs.

Image credit: Coca Cola Enterprises

In line with this strategy, CCE has invested €13 million in two strategic recycling infrastructure partnerships outside of his core business model in the past 3 years, establishing two plastics recycling joint ventures: Continuum in Great Britain with ECO Plastics, and Infineo in France with APPE.

CCE’s recycling joint ventures aim at improving the capacity for plastics reprocessing in Great Britain and France, where around half of the PET plastic disposed of is not collected for recycling and much of what is collected is being sent abroad for reprocessing – creating restrictions in the supply of locally available recycled PET. The joint ventures ensure that the increasing demand for recycled PET can be met – enabling manufacturers to have access to more rPET and to use it in their packs.

Continuum has been operational since May 2012 and is now the biggest plastic bottle reprocessing facility in the world, producing 25,000 tonnes of rPET a year – double the amount of food-grade rPET previously produced in Great Britain. The project saves around 33,500 tonnes of CO2 per year, the equivalent of taking over 15,715 cars off the road.

To date, Continuum has already supplied CCE with enough high quality rPET to include 25% rPET in all its plastic bottles in Great Britain. The facility also recycled around 15 million bottles collected at the London 2012 Olympic and Paralympic Games, returning them to the shelves as new bottles within six weeks.

Continuum recently reached the milestone of 1 billion bottles reprocessed since its opening. Internally, the Continuum facility is now the benchmark for best practice across the entire Coca-Cola System. And thirty new skilled jobs have also been created for the local area as a result of the partnership.

Continuum provides a real life example of how closed loop manufacturing can slash environmental impacts and greenhouse gas emissions.

- James Murray, editor of Business Green

In France, the Infineo joint venture has boosted the capacity of APPE’s reprocessing facility by 70%. The enlarged plant now recycles 20,000 additional tonnes of plastics per year.

In line with CCE’s commitment to inspire consumers to recyclerecycleTransform a product or component into its basic materials or substances and reprocessing them into new materials. more often, both facilities are equipped with education centres that can host visits from schools and high-schools and educate students about the importance of recycling and what things become once they’ve been recycled. Those education centres have been designed and developed in close collaboration with key actors of the waste and recycling industry.

Infineo is a powerful lever especially among the younger generation.]

- Eric Brac de La Perrière, General Manager of Eco-Emballages

More specifically, Infineo is today the first education centre dedicated to the Circular EconomyCircular EconomyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature. in France, hosting more than 5,000 students a year from schools, high schools and universities. The educational content has been designed in partnership with Eco-Emballages. Visitors can learn about the challenges of the circular economy of packaging, are encouraged to sort their waste and told about the full process of recycling.

The centre is dedicated to the recycling of all materials (plastic, paper, cardboard, glass, steel and aluminum) and offers visitors an interactive and visual experience. The centre is set out in 3 parts: giving an overview of the challenges of the transition from linear to circular economy; a tour of the APPE factory (bottle-to-bottle recycling); and fun quizzes to learn more about the second life of packaging. Since its opening in October 2013, it has already hosted hundreds of visitors.

It is through educating young people about recycling that we will enable a greater amount of recycled PET to be available to include in our bottles, which will make the circular economy a reality.

- Joe Franses, Director Corporate Responsibility & Sustainability, Coca-Cola Enterprises