Science company Solvay’s circular ambitions are seen as a key tool to delivering on its ‘One Planet’ sustainability strategy. This ambitious blueprint sets out Solvay’s pathway to a 26% reduction in emissions (with a recent SBTI commitment) and 30% reduction in biodiversity pressure by 2030.

Most people are not aware when they come in contact with a product that has been enabled by a Solvay material or process. But every day almost everyone in the world benefits in some way from the company’s invisible influence, which touches numerous areas of both work and homelife, including food and consumer goods, planes, cars, batteries, smart devices, health care applications, water and air purification systems.

Solvay is part of the wider chemical industry, which plays an indispensable role in the modern economy, converting raw ingredients into materials and compounds. In Europe alone, the chemical industry comprises more than 30,000 companies, employs over a million qualified staff and has a combined turnover of €500 billion.

To put it simply, without chemistry, there will be no green and circular rebound

Kerstin Jorna, Director General of the European Commission

How Solvay is becoming a circular chemical company

Solvay’s chemistry and materials provide the raw ingredients for thousands of its client companies. Many of these are at the forefront of today’s megatrends, including electrification, healthcare, resource efficiency and the Internet of Things.

As a key player in so many important value chains, Solvay is positioned as a powerful force for other companies’ circular economycircular economyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature. transformations, enabling them to create new forms of value while addressing global challenges.

Solvay's enabling role falls under four principal circular areas:

Material innovation - valorising waste streams from strategic markets into added value raw materials.

Better recycling - developing new processes to improve the quality of recycled material.

Product design - developing new products that are ‘circular by design’, ensuring that chemicals are safe to circulate.

Circular services - transforming the market about new business models for chemicals

Solvay’s circular ambitions are seen as a key tool to delivering on its ‘One Planet’ sustainability strategy. This ambitious blueprint sets out Solvay’s pathway to a 26% reduction in emissions (with a recent SBTI commitment) and 30% reduction in biodiversity pressure by 2030. To achieve these high level ambitions, a further subset of targets has been set out, that includes two specific circular ambitions: a growth of revenues from renewable and recycled products to 15% of total group revenue, and a 30% reduction in non-recoverable industrial waste.

Solvay's solutions are used to produce and store renewable energies (Andreas Gucklhorn/Unsplash)

Solvay's circular projects - some examples

A new bio-based supply chain for safe and circular materials

Not all materials are fit for a circular economy. Some contain chemicals that are hazardous for humans and the environment. These chemicals are needed to deliver on performance such as flexibility or durabilitydurabilityThe ability of a product, component or material to remain functional and relevant when used as intended., but once the use period of the product is over, these same chemicals present challenges for safe recovery and recycling.

Solvents are a good example. These are a large family of liquids that are used as a carrier for detergents, paints, inks, perfumes and many other products. Historically solvents like many other chemicals, have been derived from finite resources, such as crude oil. So as well as increasing the safety of its chemistry, Solvay is also striving to shift away from oil-based inputs towards renewable, bio-based feedstocks.

An industrial complex in Brazil shows how these two strands come together. In October 2020, Solvay inaugurated its second plant dedicated to the production of Augeo, a line of bio-based, non-toxic solvents, providing a circular alternative to the surface care and coating industries. The main feedstock for Augeo is glycerol, a natural compound derived from animal or vegetable fats.

Chemical innovation alone will not deliver a circular chemical industry. Pricing is a real issue when considering a switch to bio-based materials. As Isabelle Gubelmann-Bonneau, Solvay’s Circular Economy VP observes:

“The value chain based on oil derivatives is well established; now it’s a matter of making the bio-based value chain competitive. A systemic collaboration to transform the value chains could be a solution to explore”

Unlocking a circular value ecosystem for EV batteries

The large-scale transformation of vehicle fleets from fossil fuel combustion engines to electric vehicles (EVs) is seen as a key requirement for achieving the Paris climate change agreement.

However, increasing the number of EVs on the road per se will not on its own be enough to drive down emissions. To achieve their full climate mitigation potential, EVs will also need to be charged using clean energy, and importantly the materials and components that are used to manufacture EVs, need to be managed in a circular way. This means extending the use life of vehicles, as well as their constituent components and materials, to conserve embodied energy and resources, and avoid energy intensive extraction and processing of virgin raw materials. Creating a more circular system for EV batteries is seen as a major part of this challenge.

Batteries comprise about 25% of a vehicle’s overall weight, and have a highly complex material composition. During hundreds of charging cycles, the battery gradually degrades until it can no longer be used, but the recovery of its valuable constituent materials is extremely difficult because of the battery’s complex assembly. Some degree of material recycling from dead batteries has existed for many years, for example the plastic, aluminum and copper used in the casing. However recycling of the rarer and more valuable technology metals, has so far not scaled up.

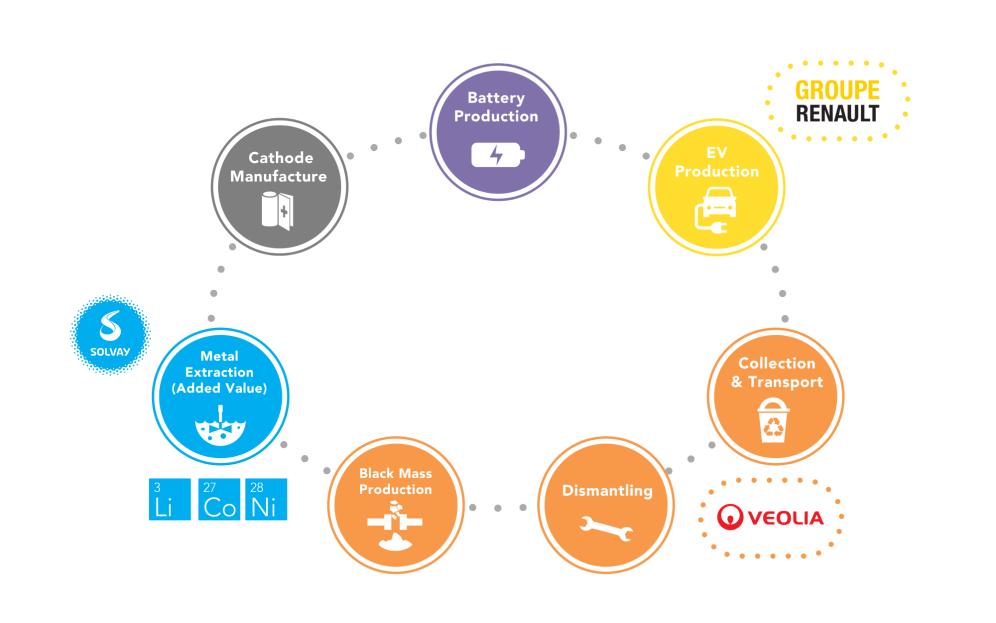

To address this, Solvay has partnered with Veolia and Renault, establishing a consortium that includes car manufacturers and EV battery producers. The overall goal is to coordinate, collaborate and leverage respective competence across the battery value chain, with the overall aim of closing the material loop of EV batteries .

A circular value chain for EV batteries

Solvay’s specific role in this consortium will be to scale up innovative chemical processes that extract and purify metals such as cobalt, nickel and lithium, from sliced up battery material supplied by Veolia. Solvay’s processes will transform this heterogenous ‘black mass’ into high quality metals that will be reused to manufacture new batteries, in theory enabling an infinite loop in which old batteries become the feedstock for new ones.

Biodiversity benefits

By implementing circular economy models and innovations, Solvay will be able to get closer to their One Planet goals. For instance, circulating EV materials through a closed loop will reduce the habitat disturbance and other environmental impacts related to extracting and processing new materials, thereby reducing the environmental footprint of future EV batteries — leaving room for biodiversity.