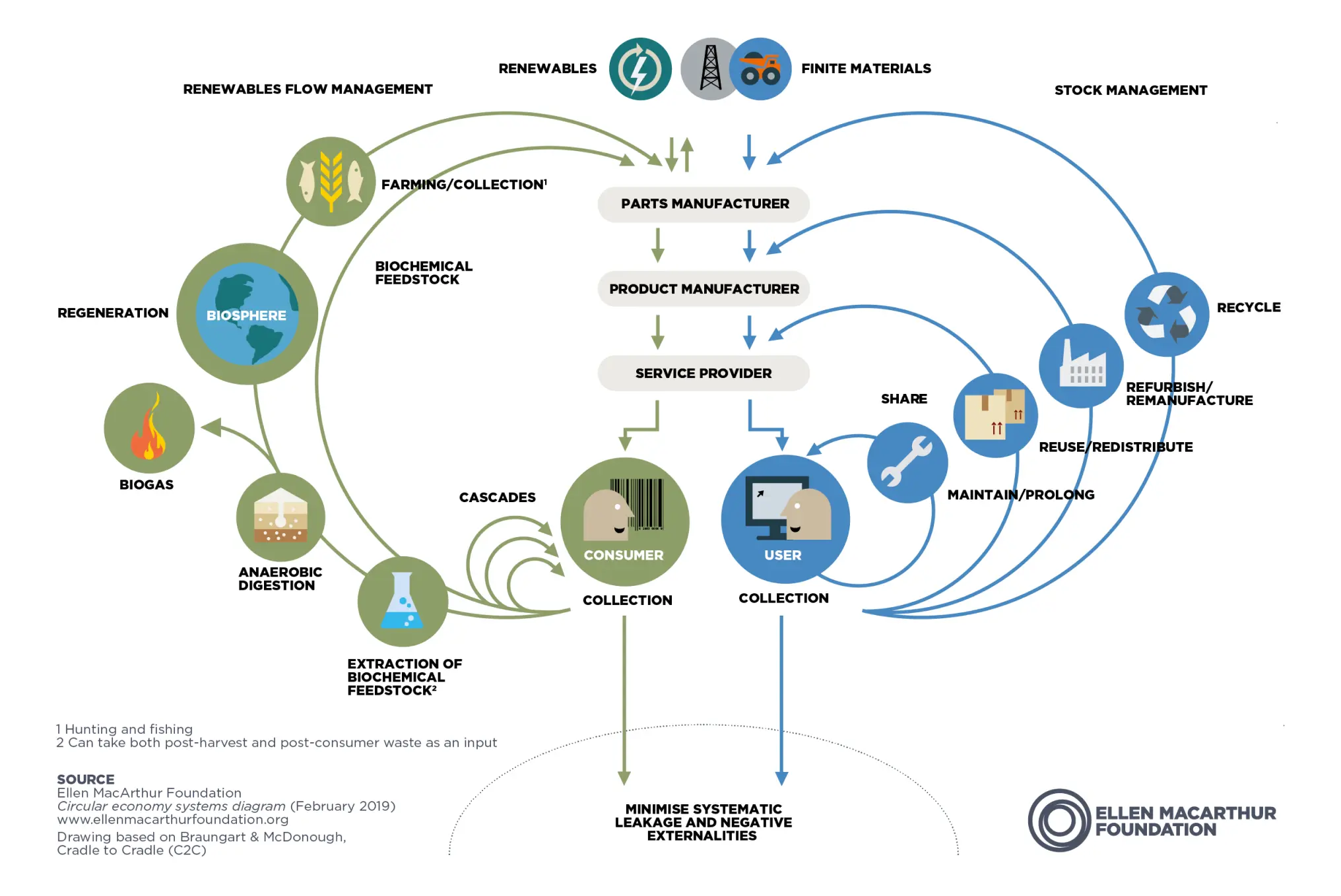

The second principle of the circular economy is to circulate products and materials at their highest value. This means keeping materials in use, either as a product or, when that can no longer be used, as components or raw materials. This way, nothing becomes waste and the intrinsic value of products and materials are retained.

There are a number of ways products and materials can be kept in circulation and it is helpful to think about two fundamental cycles – the technical cycletechnical cycleThe processes that products and materials flow through in order to maintain their highest possible value at all times. Materials suitable for these processes are those that are not consumed during use - such as metals, plastics and wood. and the biological cyclebiological cycleThe processes - such as composting and anaerobic digestion - that together help to regenerate natural capital. The only materials suitable for these processes are those that can be safely returned to the biosphere.. In the technical cycle, products are reused, repaired, remanufactured, and recycled. In the biological cycle, biodegradable materials are returned to the earth through processes like compostingcompostingMicrobial breakdown of organic matter in the presence of oxygen. and anaerobic digestionanaerobic digestionMicrobial breakdown of organic matter in the absence of oxygen..

Technical cycle

The most effective way of retaining the value of products is to maintainmaintainKeep a product in its existing state of quality, functionally and/or cosmetically, to guard against failure or decline. It is a practice that retains the highest value of a product by extending its use period. and reusereuseThe repeated use of a product or component for its intended purpose without significant modification. them. Take a phone for example: it is far more valuable as a phone than as a pile of components and materials. So the first steps in the technical cycle are focused on keeping products whole to retain the maximum possible value. This could include business models based on sharingsharingThe use of a product by multiple users. It is a practice that retains the highest value of a product by extending its use period., so users get access to a product rather than owning it and more people get to use it over time. It could involve reuse through resale. It could mean cycles of maintenance, repairrepairOperation by which a faulty or broken product or component is returned back to a usable state to fulfil its intended use., and refurbishment.

Eventually, when the product can no longer be used, its components can be remanufactured. Parts that cannot be remanufactured can be broken down into their constituent materials and recycled. While recycling is the option of last resort because it means the embedded value in products and components are lost, it is vitally important as the final step that allows materials to stay in the economy and not end up as waste.

Biological cycle

Biodegradable materials that cannot be reused, like some food byproducts, can be circulated back into the economy in the biological cycle. By composting or anaerobically digesting organic materials, valuable nutrients, such as nitrogen, phosphorous, potassium, and micronutrients, can be used to help regenerate the land so we can grow more food or renewable materialsrenewable materialsMaterials that are continually replenished at a rate equal to or greater than the rate of depletion. like cotton and wood.

Some products, like cotton clothing or wooden furniture, can be circulated through both the technical and biological cycle. They can be maintained, reused, repaired, and sometimes even recycled, but eventually they can be returned to the biological cycle from which they came. Composted or anaerobically digested, they can feed the soil to grow new cotton or wood.

Design is key to success

In order for products to successfully be circulated in either the biological or the technical cycle, it is essential they have been designed with their eventual circulation in mind. There are many products in our current economy that cannot be circulated in either cycle and end up as waste. There are products that fuse technical and biological materials in such a way that we can’t separate them and circulate them – for example, textiles that blend natural and plastic fibres.

If designers thought about how their product could fit into the technical or biological cycles after use, that product could be made with that onward path in mind. For example, products destined for technical cycles would benefit from being easy to repair and maintain, easy to take apart, and made of modular components that can be replaced. They could be durable enough to withstand the wear and tear of many users. And they could be made from materials that are easily recycled.

If products like wooden furniture were designed – as well as to be easy to maintain and repair – with the biological cycle in mind, their biodegradable materials (like wood) would be easily separated from their technical materials (like screws) and if glues and paints were used they would be biodegradable. Other products, like takeaway food containers, can be designed to be compostable after one use so that they increase the chances of the food scraps they contain returning to the soil.

Examples of companies designing for circulation

There are many innovative companies already designing their products with recirculation in mind. Ecovative makes compostable packaging from agricultural byproducts (the parts of crops that cannot be eaten) and mycelium (mushroom roots). The packaging works like expanded polystyrene to protect fragile items in transit, but it is from a renewable source and does not contribute to plastic waste. Mycelium is a fungal network of threadlike cells that acts like a natural, self-assembling glue. It grows in 5-7 days without needing any light or water, digesting agricultural by-products and binding into any shape needed. At the end of the process, the material goes through a dehydration and heat treating process to stop the growth and to ensure the absence of spores or allergens. Once used, it can be safely composted and returned to the soil.

Ecovative packaging can be returned to the earth after use as part of the biological cycle.

Resortecs has developed an innovative solution to improve the recycling of stitched clothes such as jeans and jackets that need to be taken apart before their constituent materials can be recycled. The existing disassembly process is time-consuming and costly, as the garment and its components are held together by a synthetic high-strength thread – in most cases made of polyester. Before recycling, the pieces of the garment have to be separated and the thread removed, otherwise the quality of the recycled product will be compromised. Resortecs has designed a dissolvable thread, making the disassembly process easier and helping to keep textiles in the economy.

Resortecs threads are dissolved using a commercial oven and are available for different melting-points (150C, 170C and 200C) depending on the type of garment that is being taken apart. The Resortecs solution allows up to 500 kg of clothing to be dismantled at the same time.

Resortecs' innovative dissolvable thread helps keep textiles in circulation by making it easier to disassemble clothing.

Many companies are adopting reusable packaging as a way to keep materials in circulation. Loop, which operates in France, the UK, and the US, is a reuse platform that offers big brand products, such as Tide detergent and Heinz Ketchup, in reusable packaging. When a container is empty, there is no need for the customer to clean or sort it. It is either collected from their home or can be dropped off at participating stores. The containers are then professionally cleaned, refilled, and used again.

Time for action

By adopting the second principle of the circular economy – circulate products and materials – we retain the value embedded in products and the materials they are made from. By doing so, we keep finite materialsfinite materialsMaterials that are non-renewable on timescales relevant to the economy, i.e. not geological timescales. in the economy and out of the environment, and safely return biodegradable materials to the earth.