name:

Better World Fashion

A piece of wisdom from circular economy thought-leader Walter Stahel: “reuse what you can, recycle what cannot be reused, repair what is broken, remanufacture what cannot be repaired”.

This rule of thumb is becoming more widely appreciated for technical products like engines, computers and printers. Perhaps it’s the use of rigid, durable materials like metal and plastic that make extending a product’s life more seem more attainable. How well does this approach apply to very different category such as clothing?

A common response is that the current trend towards fast fashion poses a real challenge to moving towards the ‘inner loops’ of a circular economycircular economyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature., but it was precisely this trend that inspired Reimer Ivang, Karsten Lund and Kresten Thomsen to establish Better World Fashion. According to Reimer, for better or worse the public have “shown that they want fast fashion...so do we try and re-educate them or provide a positive alternative without the complexity?” The aim of Better World Fashion was to do just that, offering high-quality, durable goods with a business model that embraces changing styles and preferences.

We wanted to come up with a business model in which nobody loses, and the most extreme way to do that is reusereuseThe repeated use of a product or component for its intended purpose without significant modification..

- Reimer Ivang

It’s an idea that has hovered on the fringes for some time, with other startups like Vigga and Mud Jeans also exploring this niche. For Better World Fashion, the decision to specialise in leather - and initially leather jackets - was important for three main reasons. Firstly, rearing cattle for food or leather production is highly energy and resource intensive under today’s methods. Secondly, it enables the company to explore the inner loops of a circular economy, focusing on the higher value re-use activities rather than simply materials cycling. Finally, leather is one of few clothing materials that actually gets better the more it’s used, improving the look and feel of the garment. These factors led Reimer, Karsten and Kresten to seek to prevent old or ‘unfashionable’ leather products from being disposed of or unused in closets.

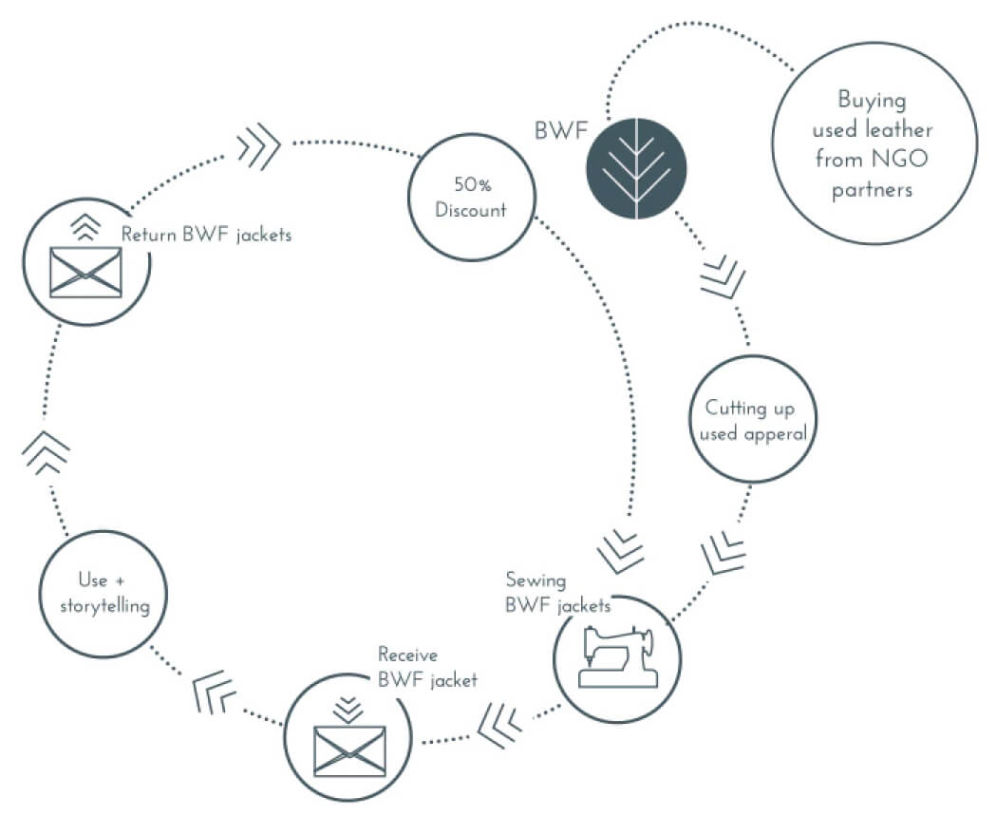

The jackets available today are made from re-used leather collected from NGOs across Denmark and as much re-used polyester and aluminium as possible. Customers obtain one of the jackets either through a monthly lease arrangement, or an outright purchase with buyback option. The customer can hang onto the jacket for as long as they like, but when they’re done with it, the onward use phase is clearly in place. Those that purchased a jacket can send it back to Better World Fashion receiving 50% discount on a new garment. Alternatively, the customer can transfer the lease to an admiring friend or relative.

The patina of the material isn’t the only thing that develops over time. Owners can share the story of their jacket which is also passed on to the next user, something Reimer describes as a ‘family tree’ for clothing. Each garment has a unique ID and profile to give customers a better understanding of the story of the product. This works in conjunction with any scars or blemishes the jacket has picked up during its use. The repairs are taken care of by Better World Fashion, with the imperfections and the story behind them harnessed as a unique design element, giving the jacket a ‘one off’ appeal for subsequent customers. At the point when a jacket can no longer be repaired, as much of the leather as possible is re-used in new jackets or, in the manufacture of bags, gloves, and other smaller accessories.

All our jackets are just as different as our customers. Using reused leather, you will never find two jackets that are identical.

- Reimer Ivang

Getting the right price point has been a challenge for the startup. Reimer Ivang thinks that part of this is because people naturally associate re-use with lower prices, and some have been surprised to learn that Better World Fashion’s re-used jackets cost the same as their new ones. There are couple of reasons for this. Firstly, it’s a way of factoring in an unseen costs of environmental impairment involved in making the jacket, as “the consumer is currently not knowledgeable about the externalities - there is a huge price paid where the jackets are produced”. Secondly, the pricing model is a response to the belief that re-used items are of inferior quality, and therefore deserve to be cheaper. Especially in the case of leather, the product improves as it’s used, in terms of style and performance. Unsurprisingly, Reimer says that one policy change that could help would be the reduction or removal of VAT on remanufactured products.

For business models that favour ‘access over ownership’, something that is often called into question is whether customers will be prepared to wear someone else’s clothes, sleep in someone else’s bed, or lend a stranger their car. What about the stories that users don’t add to the history of their jacket? The comparison Reimer uses is one we’re all familiar with, reminding that “when you go to a hotel - you know the bed has been slept in before. Using stuff that others have used is not new!” Sure enough, with paying for performance, as opposed to ownership, taking off in a number of industries, there does seem to be a new type of citizen that’s open to this type of business model.

Getting access to funding can be make or break for a new startup, and those behind Better World Fashion have come up against an unlikely roadblock. In Reimer’s view, too many funding programmes today show a preference towards new developments in technology such as the Internet of Things. Because his company focuses on business model innovation, there’s a misplaced perception that it doesn’t display enough of an innovation leap. This is a shame, as the model actually shows an understanding of materials, manufacturing and business strategy that is at the cutting edge of our understanding of the world in 2016: one of volatile prices, supply risks, environmental constraints, and beginning to chart a course for a circular economy.