In brief

Industrial hemp is an ingredient with plenty of potential. It's a robust, resilient, and adaptable crop that needs relatively low inputs and little water. It can be more efficient at absorbing carbon dioxide than agroforestry, increases local biodiversity, and supports regenerative farming practices due to its natural disease and pest resilience and ability to restore soils. Its seeds are rich in protein, vitamins and fibre and can be used in a variety of food applications.

Prohempotic uses hemp as a main ingredient in its new line of food products, including salad dressing, crackers, and pet treats. This series of products takes a ‘whole seed’ approach, using all of the ingredients that can be derived from a seed and combining them with often-upcycled ingredients. These products demonstrate all four circular design for food principles by using ingredients that are diverse, lower impact, upcycled, and grown within regenerative systems.

How it started

Founder and CEO, Jamila La Malfa-Donaldson, studied industrial hemp waste material for her PhD at Aberystwyth University. After identifying a number of food product ideas in the course of her research, she set up Prohempotic to commercialise promising food applications and hopes that hemp can become a mainstream alternative to soy. She works with a research technician from Aberystwyth University in the UK on product development.

Product development is being supported by a grant from the Big Food Redesign Challenge, which Prohempotic is participating in.

What’s happening?

The company has developed prototype products designed to use all the ingredients that a hemp seed can provide: oil, hemp seed hearts (the soft, inner part of the seed), and protein powder.

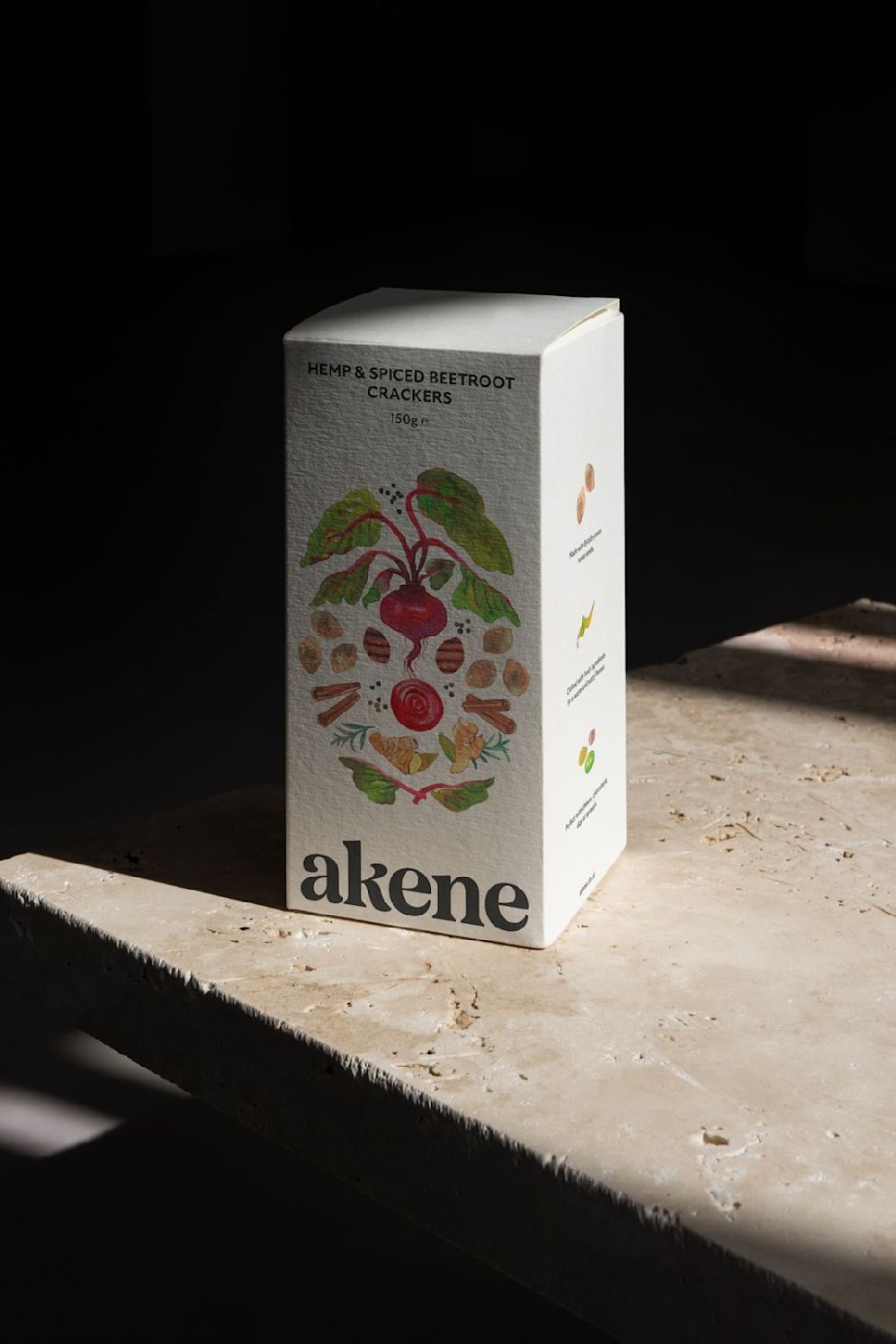

The initial focus is on crackers, launched under the Akene brand. Protein powder is extracted from the crop and mixed with other UK-grown ingredients including organic spelt, buckwheat, and surplus beetroot. Later, this will be supplemented by additional products which use the full range of seed-derived ingredients: a salad dressing, using oil pressed from the seeds and vinegar made from supermarket fruit and vegetable waste, and pet treats, which use the coarser protein meal.

Prohempotic has developed relationships with farmers across Wales and is working with them to foster practices that support regenerative outcomes. The hemp is grown with no tilling, irrigation, or the addition of pesticides or herbicides. Methods are being established to collect data and track regenerative outcomes at field level.

Packaging options that align with circular economycircular economyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature. principles are being explored, with current options including aluminium tins, compostable bags, and seaweed- or hemp-based paper. The Challenge has provided access to major retailers to find retail channels and raise awareness of the brand.

Why it’s an example of the circular economy

The circular design for food framework incorporates four design opportunities – upcycling, use of lower impact ingredients, and use of diverse species/crops, grown in regenerative systems. Prohempotic employs all four of these design principles in its food products.

Circular Design for Food Framework

Hemp is both a lower impact ingredient and diverse crop. Fast-growing, it can quickly crowd out other plants and is naturally resistant to many pests and diseases, meaning it needs little maintenance, pesticides, fertilisers, or irrigation. Reduced chemical inputs reduce the potential for run-off and pollution, while deep root systems prevent soil erosion. Its dense leaves become a natural soil cover, reducing water loss and supporting soils to regenerate. These qualities lend hemp to integration in diverse arable crop rotations as it can provide effective weed control and break up pest and pathogen cycles while restoring soil nutrition. It also sequesters carbon at a similar rate to a young forest, but can grow in just five months.

Prohempotic combines hemp with upcycled ingredients, finding a use for products that would otherwise be wasted. Eliminating waste is a key principle of the circular economy, yet up to 20% of food is lost or wasted globally.

By working closely with farmers at the prototype stage, Prohempotic is ensuring that regenerative outcomes are at the heart of product design, while creating a robust business for farmers. Hemp is a versatile plant that can be used to make textiles, construction materials (such as hempcrete), and cosmetics, as well as food products, and so demonstrates how biological materials can be used across multiple industry sectors.

Lessons learnt

The UK’s supply chain for hemp is in its infancy and so making full use of all the products provided by a hemp crop and taking advantage of the full-plant opportunities is challenging. This underdevelopment means there are fewer actors and fewer collaboration opportunities. Prohempotic intends to lead by example. By using state-of-the-art processing techniques to develop bespoke methods to maximise the quality, flavour, and functionality of hemp-based products, the company hopes to stimulate demand for hemp products and in doing so help to evolve the ecosystem.

Limited processing locations can also increase the transport footprint of hemp-based products. Prohempotic plans to progress hemp growing and processing in the UK, building on established industries in France, the US, and Canada, in order to reduce transport requirements.

Current extraction methods do not obtain all the protein available from hemp seeds. Prohempotic is currently co-developing a method with Aberystwyth University to maximise protein extraction.

As a novel ingredient, licensing restrictions can be a barrier for farmers. There are also regulatory difficulties surrounding hemp crops, which can dissuade farmers from planting crops, for example, it cannot be grown near footpaths or schools. However the UK Home Office has recently announced changes to the framework that will remove restrictions on where hemp can be grown on a licenced farm, which will facilitate better crop rotation. Prohempotic works closely with farmers to help them understand the licensing process.