Connectivity enables complex supply chains and is accelerating the transition to circular business models and practices.

Digital technologies are driving a profound transformation of our lifestyles and economy. From smart thermostats that can be controlled from a phone, and sensors that tell drivers when tyre pressure has dropped, right up to smart grids that are enabling the effective integration of renewable energy resources, the Internet of Things (IoT) – which enables physical objects to exchange data – is enabling us to interact with the world around us in new ways.

In industries with high-value assets, early investment into IoT technology has brought significant gains. Billions of sensors are used in the transport, manufacturing, and engineering sectors to detect the optimal moment for preventative maintenance, improving the operating lives of machinery and reducing waste. Rolls Royce, for example, has long used sensors across its 4,500-strong fleet of engines to collect data about engine temperature, fuel flow, air flow, and pressure, analysing the data to identify maintenance problems before they emerge and economise fuel use. Wind farms use remote sensing to detect everything from weather conditions to blade vibrations, using the data to prolong the use of turbines.

As connectivity has increased – driven by the ubiquity of wireless networks, maturation of mobile networks, ready availability of Big Data, and falling costs of monitoring and analysis technology – more and more businesses are realising the opportunities presented by IoT. McKinsey estimates that around 25% of businesses are now using IoT technologies, and in 2020 IoT solutions generated USD 1.6 trillion in economic value. It is a key part of the digital revolution, dubbed Industry 4.0, that is blurring the lines between physical, digital and biological spheres.

IoT and the circular economy

But the biggest IoT gains are likely to be still ahead of us, particularly in the business to business (B2B) sector, with McKinsey suggesting it will benefit from 65% of the total value released by IoT by 2030. Guiding this wave of change by applying circular economy principles can create value, and generate wider benefits for society, while building a system that can run in the long-term.

A circular economycircular economyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature. aims to, by design, eliminate waste and pollution, keep materials in use at their highest value for as long as possible – by reusing, repairing, refurbishing, and recycling products and their constituent parts – while at the same time regenerating nature.

IoT is now considered a crucial element of a circular system. It gives organisations better visibility of supply chains, bringing greater opportunities for control and innovation, and enables the creation and processing of the data required to fulfil the complex demands of circular supply chains, such as material tracing, reverse logisticsreverse logisticsSupply chains dedicated to the reverse flow of products and materials for the purpose of maintenance, repair, reuse, refurbishment, remanufacture, recycling, or regenerating natural systems., decentralised production and remanufacturing.

The potent combination of blockchain technology and IoT can accelerate this transition to a circular economy. By enabling a central, immutable ledger of transactions it brings higher levels of transparency across the supply chain, ensuring traceability, ethical sourcing and more effective material flows.

Equally, IoT can be used to extend product use by helping to maintainmaintainKeep a product in its existing state of quality, functionally and/or cosmetically, to guard against failure or decline. It is a practice that retains the highest value of a product by extending its use period. it – detecting faults and enhancing the provision of technical support, and maximising assets by, for example, shutting them down when not in use – and empower new, circular business models such as product-as-a-service.

IoT technologies are already altering circular economy practices and existing business models, allowing businesses and organisations in a broad range of industry sectors to eliminate waste, circulate materials, and regenerate nature. So what are the practical applications?

Eliminating waste

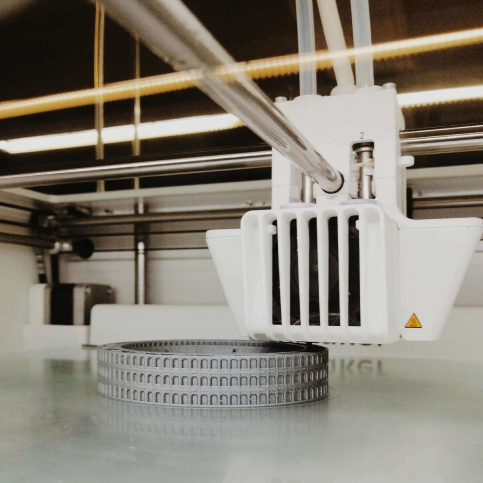

IoT can be harnessed to enable the elimination of waste. Combining IoT – the ability to monitor complex systems in real time – with 3D printing (agile manufacturing) can eliminate the need to store large inventories of spare parts in physical warehouses. For example, sensors in vehicles can be used to detect faulty parts in real time and prepare a replacement by accessing a virtual inventory of files, printing parts on-demand in a nearby location ready for engineers to install.

Only producing parts that are needed has obvious material benefits, but there are positive secondary implications too. With the right equipment in place, an aeroplane with a fault, for example, can be repaired on landing, no matter where it is, rather than having to wait (sometimes days) for the replacement part to be tooled, manufactured, or shipped to the right location. That means the service can be operated with fewer vehicles.

The same principle is true of retail. Historic data on purchasing patterns gathered through IoT allows retailers to more accurately predict demand, while stock levels, long monitored manually using bar codes, can be seen in real time through blockchain tracking. Together, these innovations mean businesses can serve customers with around 20% less global inventory.

Closing the material loop

The circular economy keeps products and materials in circulation through processes such as reusereuseThe repeated use of a product or component for its intended purpose without significant modification., repairrepairOperation by which a faulty or broken product or component is returned back to a usable state to fulfil its intended use., remanufactureremanufactureRe-engineer products and components to as-new condition with the same, or improved, level of performance as a newly manufactured one., and recycling. Reverse logistics are an important element of these loops, the means by which manufacturers recover products and materials for recirculation.

IoT can solve difficult material processing problems to enable these more sophisticated reverse flows. Smart warehouses, for example, are already equipped with evermore sophisticated technology – such as robotic pickers, wearable devices for warehouse operatives, automated guided vehicles (AGVs), and radio-frequency identification (RFID) tags, meshed together using the IoT – to make the outflow of goods through them fast and efficient.

However, 20% of online retail sales are returned - twice as many as bricks-and-mortar purchases. By implementing a strong reverse logistics system, companies enable better circulation of goods and could limit overproduction. IoT sensors within this process can assess products for resale, and automatically return usable goods to the stock inventory to avoid waste. Unusable goods can be separated for remanufacture, or the raw materials identified for reuse or recycling. By applying these principles, Intel is now able to reuse or reclaim 99% of its returns, which generated around USD 30 million in 2020.

Material identification is a further, useful application of the IoT in the circular economy. Take the problem of contaminated collection streams. The process of manually sorting mixed material types into the right channels is laborious and expensive, if even possible. Sensor-enabled bins can sort recycling into the right streams by identifying, sorting and crushing different materials, to reduce waste and recirculate materials. Such developments are only set to improve as material identification becomes more sophisticated with advances in blockchain tracing technology.

In the future, academics believe the IoT could enable the development of a larger scale marketplace for connecting buyers and sellers of collected materials to refine global supply chains. For example, businesses could be automatically invited to bid for commodities when a critical quantity of accurately sorted scrap materials is reached in a collection facility. This has the potential to stimulate a competitive market for reclaimed materials while returning high-quality materials to circulation.

Regenerative applications

The regeneration of nature is a key principle of the circular economy and also enabled by IoT innovations. For example, circular business models that increase utilisation of cotton clothing – such as H&M’s IoT-enabled clothing rental and swapping service – could reduce demand for cotton, and therefore the amount of land needed to grow it, leaving more space for nature.

Where land use is needed, the IoT can facilitate regenerative farming practices, which actively rebuild biodiversity, improving soil health and sequestering carbon, while keeping farmlands productive, reducing pressure to expand them.

For example, grazing technology from Norwegian company Nofence means livestock can be restricted to certain areas using geographical – rather than physical – ‘fences’, set on a smartphone app that communicates with a solar-powered collar on each animal which emits an audio warning when they stray out of zone. Cows, goats and other small animals are moved steadily from pasture to pasture, rebuilding soil organic matter and health as they go, in a way that would be prohibitively labour-intensive with physical barriers.

Similarly, using IoT platforms to make full use of the land and resources available gives space and supplies for nature to flourish alongside areas of cultivation. Technology such as WiseConn’s DropControl uses interconnected sensors to monitor soil moisture, wells and weather stations and allows farmers to wirelessly control water use. This optimises irrigation and can save up to 30% on water consumption.

Regenerative applications extend beyond smart agriculture. IoT-enabled drones can plant trees in deforested areas six times faster than human labour, rapidly restoring tracts of forest, and governments deploy IoT sensors and technology to monitor fishing boats, preventing depletion of marine stocks in their fisheries and allowing the natural ecosystem to regenerate alongside.

IoT: scaling the circular economy

The circular economy generates a different set of needs to the current linear paradigm, from advanced collection and sorting of materials, to circular production technologies and interactive platforms. The IoT is a powerful tool in managing the inherent complexities of circular supply chains and business models, with business leaders identifying transparency tracking and cross-sector collaboration as areas where it can drive progress.

However, the technology is not without its drawbacks. Reliance on complex, internet-dependent systems leaves organisations vulnerable in the event of power or connectivity outages, while connectivity also exposes the technology to the risk of data breaches and cybersabotage. In 2021 there were more than 900 million cyberattacks on IoT devices, at a rate that some experts believe is escalating.

Interoperability is another challenge. Deloitte points out that the IoT is “an inherently shared ecosystem and operating model that crosses public and private sectors”, but “while much of the promise of the IoT lies in the ability to aggregate data, today data is generated in different formats, and sensors connect to different networks using different communication protocols”. Formal global standards would allow for greater security and collaboration, but appear to be some way off, leaving companies to rely on voluntary alignment in the meantime. To truly accelerate the transition to a circular economy, work needs to be done to develop a standardised IoT architecture that enables maximum interoperability.

Regardless of the challenges, PWC defines the IoT as one of Eight Essential technologies that have the power to transform business, and it hasn’t yet begun to realise its full potential. It is projected that the IoT could add USD 5.5 trillion of economic value by 2030 (although the technology has previously fallen short of growth predictions against headwinds of change management, cost, talent, and cybersecurity). Consciously building these innovations and infrastructure along circular principles could accelerate the transition to an economy that can actively regenerate the natural world.