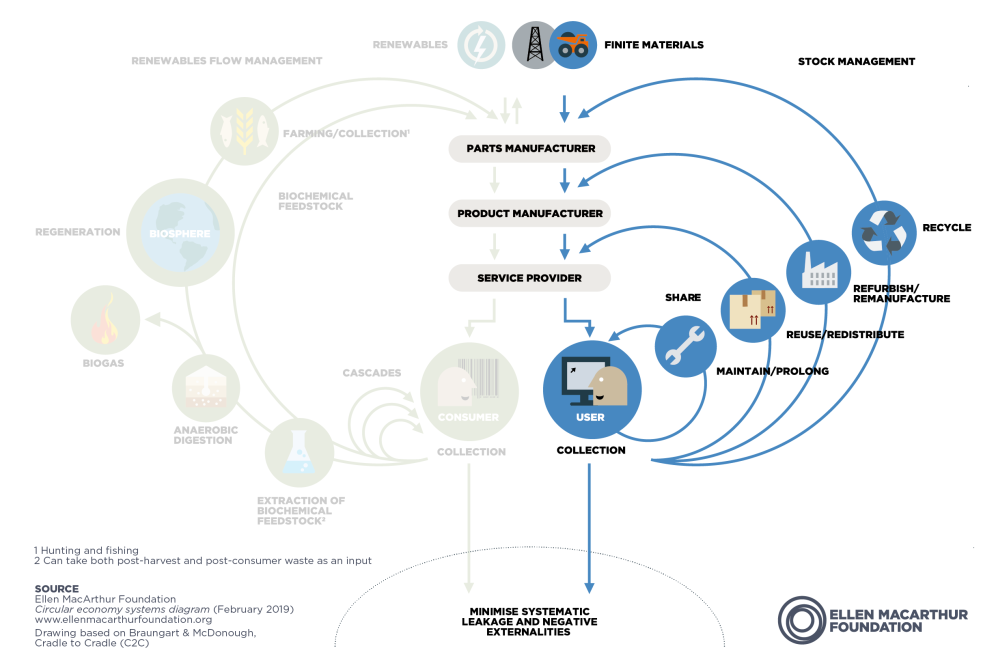

On the right-hand side of the butterfly diagram is the technical cycle, relevant for products that are used rather than consumed. This page will focus on the different stages of the technical cycle and look at how each step allows materials to remain in use rather than becoming waste.

The diagram shows that smaller inner loops are surrounded by the larger outer loops. These inner loops are where most value can be captured because they retain more of the embedded value of a product by keeping it whole. Take a smartphone, for example – a working phone is worth more than the sum of its parts because the time and energy that went into making it is not lost. Therefore, inner loops like sharingsharingThe use of a product by multiple users. It is a practice that retains the highest value of a product by extending its use period., maintaining, and reusing should be prioritised above the outer loops that see the product broken down and remade. These loops also represent a cost saving to customers and businesses as they make use of products and materials already in circulation, rather than investing in making them new.

The outermost loop, recycling, is therefore the stage of last resort in a circular economycircular economyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature., because it means losing the embedded value of a product by reducing it to its basic materials.

Working from the innermost loop, this page goes through the basics on each step. It is important to bear in mind from the outset that each of these steps will work best if the products are designed for that step. That may mean making items intended for sharing or reusereuseThe repeated use of a product or component for its intended purpose without significant modification. more durable so they withstand intensive use, it may mean designing products so that they can easily be repaired, designing them to be modular so components can be replaced and remanufactured, or designing products with materials that can easily be separated for recycling. It is also important to design for multiple loops, for example making a repairable product from recyclable materials.

Sharing

Sharing is the first port of call in the technical cycletechnical cycleThe processes that products and materials flow through in order to maintain their highest possible value at all times. Materials suitable for these processes are those that are not consumed during use - such as metals, plastics and wood. and, while not appropriate for all products in the economy, it has the power to dramatically increase the utilisation of many products.

A great example of this is tools. You may have heard the stat: the average power drill is used for just 13 minutes in its entire life. That is shocking underutilisation – and yet still many of us own one. Why not share? Community tool libraries, like this one in Toronto, are a great way to facilitate this. Users pay by subscription, gain access to higher quality tools than they would buy for themselves, and declutter their home at the same time. Libraries like this are popping up in communities all over the world and not only for tools.

Sharing can be applied to a variety of product types. There are a growing number of platforms that allow users to wear clothes from shared wardrobes. There are car-sharing systems in cities all over the world. There are platforms like Airbnb that allow people to share spaces. And there are insurance companies that provide micro-insurance for those looking to earn extra money by listing their items on peer-to-peer platforms but are worried about potential damage.

There are also platforms designed to enable businesses to reap the rewards of the sharing economy, such as Rheaply, a B2B service that allows organisations to make the most of equipment that would otherwise remain idle.

Maintaining

If sharing is a way to increase the intensity of product use, another way to maximise the value of a product is by prolonging its usable life. Maintenance is an important way of keeping products at a high quality and guards against failure or decline.

When you think about maintenance, you might think about taking a car for a service, or shoring up your home against the elements, but maintenance can be applied to most products that suffer wear and tear. For example, Clothes Doctor empowers people to look after their clothing by sharing knowledge about care and maintenance.

Reusing

The next loop in the technical cycle of the butterfly diagram is reuse. Like sharing and maintaining, this step keeps products in use in their original form and for their original purpose. Reuse business models are cropping up all over the economy, notably in packaging. Reusable packaging is one of the most effective ways of tackling packaging waste, particularly plastic, and is being adopted by businesses across industries, from food and drink to cosmetics and home cleaning.

Another booming reuse industry is in clothing. More and more people are selling their unwanted clothing and buying clothes from resale platforms, often at a fraction of the cost of buying new. This displaces the need for a new item to be made and stops an unwanted item going to waste.

Redistributing

Redistribution is another way to keep products in use and stop them becoming waste. By diverting products from their intended market to another customer, the product is put to valuable use. For example, a fashion brand could redistributeredistributeDivert a product from its intended market to another customer so it is used at high value instead of becoming waste. unsold clothing from one store to another.

Refurbishing

Returning products to good working order is a way to restore their value. This could include repairing or replacing components, updating specifications, and improving cosmetic appearance.

Refurbishing can be carried out by individuals on their own products, or by specialists. The Right to RepairRepairOperation by which a faulty or broken product or component is returned back to a usable state to fulfil its intended use. movement aims to make changes to regulations so that products are designed in a way that makes it possible for users to repair them by themselves.

There are countless examples of companies working to keep products in use through refurbishment. A good example is in the tech industry, where there are many companies buying up used items such as mobile phones, refurbishing them, and selling them on at a fraction of their original price.

Remanufacturing

The next stage of the technical cycle is remanufacturing. This is done when products cannot remain in circulation in their current state and need more intensive work to be used again. Remanufacturing involves re-engineering products and components to as-new condition with the same, or improved, level of performance as a newly manufactured one. Remanufactured products or components are typically provided with a warranty that is equivalent to, or better than, that of the newly manufactured product.

It may require more investment in plant and machinery than do the inner loops of the technical cycle, but it means that products and components do not become waste and can remain in the economy, representing a cost saving to businesses and customers.

China has adopted the circular economy as a national priority since the late 2000s and has defined vehicle remanufacturing as a strategic sector.

Recycling

The final step in the technical cycle is recycling. This is for when a product can no longer be used and is beyond refurbishment or remanufactureremanufactureRe-engineer products and components to as-new condition with the same, or improved, level of performance as a newly manufactured one., or isn’t suitable for those steps. It is the final way of keeping in use the materials from which the product is made so they don’t become waste.

With recycling, the embedded value of a product – the time and energy invested in making it – is lost, but the value of the materials is retained. Recycling means transforming a product or component into its basic materials or substances and reprocessing them into new materials.

Designing for recycling is important for all products in the technical cycle, but especially for items that are not suitable for the other steps in the cycle. These items include single-use packaging, which is itself only appropriate when it cannot be designed out and reusable alternatives are not possible.