Philips is a global health technology company focused on improving health and enabling better outcomes for people, from healthy living and illness prevention, to diagnosis, treatment and homecare. Philips products include large scale medical equipment, such as imaging, as well as smaller medical equipment and homecare products. Philips services support the whole spectrum of activities in the health industry. The company employs approximately 77,000 employees and generates EUR 17.8 billion sales in 2022 with sales and services in more than 100 countries.

Philips’ size and the nature of the services and products it provides, means it is in a prime position to spearhead the transition to a more circular healthcare industry. Philips is working to embed the principles of the circular economycircular economyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature. into everything the company does and is developing new business models to support this, such as product-as-a-service, take-back schemes, and upgrade and refurbishment programmes. In 2022, 18% of Philips business revenue came from circular products and services; and the company already offers trade-ins on all large medical equipment.

What a circular Philips looks like

Philips’ ambition is to decouple its growth from finite resource consumption across its entire value chain. To achieve this, Philips takes a holistic approach, embedding circularity into the DNA of the company, empowering all employees to contribute, and building it into the products and solutions it offers customers. Philips also partners with others to jointly drive global change.

Increasing circularity at Philips means more effective management of resources end-to-end, through product design and business model innovation, as well as harnessing the potential of digital and emerging technology.

How Philips is making a circular transformation

Closing the loop on equipment

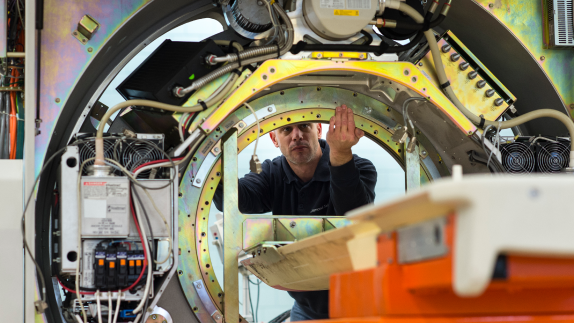

Medical equipment can be traded in by customers and refurbished by Philips. This started with large hospital equipment, like MRI systems, and will be extended to smaller equipment like patient monitors and ventilators over the next five years.

Refurbished systems

These are ‘as new’ quality with a performance guarantee. For example, Philips Circular Edition systems play a key role in the transition to a circular economy by prolonging the use life of medical hardware, which significantly reduces the demand for virgin raw materials and lowers carbon emissions.

New business models

By providing equipment through a service contract, rather than a one-way transaction, Philips maintains ownership and responsibility for the hardware, such as Enterprise Monitoring as a Service.

Smarter, more connected health services

Digital products and services can reduce emissions and material use by, for example, enabling remote interaction between patients and caregivers or extending performance of equipment via upgrades and predictive maintenance. Clinical decision algorithms and analytics can also deliver personalised, actionable insights.

A material intense industry

In the next few decades the global healthcare industry is predicted to both expand and evolve. This shift will be driven by an array of factors, such as demographic changes in developing markets, technological advances, and improved understanding of the causes of positive health outcomes.

Many aspects of healthcare delivery are very resource intense and generate large volumes of waste. For example, hospitals produce approximately 0.5 kg waste per bed per day, globally. The US healthcare system wastes more than USD 760 billion each year, due to overmedication, unnecessary services, and inefficient care delivery.

As the global healthcare sector faces up to the next few decades — both serving an increase in patients as well as grappling with the many different environmental and social challenges — circular innovation can help shape healthcare solutions that simultaneously improve lives and access to care, while also protecting the planet.

The benefits of a more circular healthcare system

The circular economy is based on three principles, driven by design: eliminate waste and pollution, keep products and materials in use, and regenerate natural systems.

However, Philips also believes that the benefits of a circular economy extend to their customers – delivering more value by improving quality and performance.

Customer benefits

Shifting to different circular healthcare solutions allows Philips customers to achieve their own ESG goals and improve their bottom line:

Service based solutions

These enhance customer investments, expand capabilities and lifespan of equipment, and increase uptime through remote services.

Trade-in schemes

These schemes capture the value of old systems and ensure responsible end-of-life management with no waste ending up in landfills.

Refurbished systems

Customers have access to high quality and performance at reduced costs, lowering the environmental impact and need to use raw materials, and making it easier to extend clinical capabilities.

Digital solutions

The amount of use equipment gets can be improved through digital technologies, helping to treat more patients per day. Also, adopting cloud-based technology can reduce material and energy use and reduce operational costs.

Business benefits

Circular economy can benefit Philips as a business, improving financial performance in three distinct ways:

Increased competitive advantage and long term value creation, as more and more customers consider the environment in procurement decisions.

Stronger customer relations and enhanced loyalty with clients leading to more repeat business through, for example, product-as-a-service offerings, take-back programmes and upgrade schemes.

Cost savings to the company through reduced material use.

“Working on healthy people and a healthy planet are two sides of the same coin”

Harald Tepper, Circular Economy Program Lead at Philips

Environmental and social benefits

Philips’ circular and other related ESG commitments support at least three of the UN sustainable development goals (SDGs):

SDG 3: Healthy lives and promote well-being for all at all ages

SDG 12: Sustainable consumption and production patterns

SDG 13: Action to combat climate change and its impacts

To help measure environmental benefits, Philips has incorporated Life Cycle Analysis as the backbone of its EcoDesign process to determine the environmental impact at each stage of a product’s life — from raw material extraction through its use phase(s) to final disposal and recycling.

Through digitalisation, resources can be used more effectively and the use of hardware can be reduced, thereby reducing CO2 emissions.

Digitisation also facilitates a faster shift towards distributed and inclusive models of healthcare, allowing wider access to care thereby contributing to Universal Health Coverage (UHC). Philips Lumify, a mobile ultrasound machine that connects directly with iOS or Android devices of the health-care worker (instead of separate patient monitors), exemplifies how digital integration can create a more distributed and affordable healthcare system.

To illustrate the potential of the shift to circular and more digital healthcare:

Replacing physical visits with telemedicine appointments resulted in a significant 40-70 times decrease in carbon emissions.

Switching to cloud storage reduces server requirements by 75% and can result in energy savings of up to 93%.

More intelligent and efficient usage of software can lead to 30 - 90% less energy use as well as reduced consumption of material.

Two important enablers of Philips’ shift towards circularity

Strategy and Leadership

Philips’ circular transformation journey began in 2012, a year after Frans van Houten took over as CEO. For his first five-year strategy, he took the bold step of embedding circular economy explicitly into Philips’ strategy, justifying this decision using both a business rationale of increased competitiveness, cost savings and better customer relationships, as well as the need to do business responsibly in the light of environmental impact and finite resources.

To support Philips’ circular economy 2016 - 2020 business strategy, a set of ‘circular KPIs’ was developed as part of a broader set of sustainability targets. The formalisation of these circular KPIs, along with a concrete target of 15% of revenues from circular products and services, were the key mechanisms to ensure that Philips was progressing on its circular transformation journey. In addition, Philips is the world’s first health technology company to have its CO2 emission targets approved by the Science Based Targets initiative.

In September 2020, Philips updated its commitments across all the Environmental, Social and Governance (ESG) dimensions to guide the execution of their 2021 - 2025 strategy and support delivery of the UN Sustainable Development Goals.

Zooming in on circular economy specifically, by 2025 Philips is committed to:

Generating 25% of sales from circular products, services and solutions

Closing the loop on all professional medical equipment including responsible end-of-use management

Embedding circular practices at all Philips’ sites, including sending zero waste to landfill

Changing mindsets of Philips employees

Having established a direction of travel and clear targets, Philips set about ensuring that key internal and external stakeholders were both fully invested in the plan and equipped with the necessary skills and knowledge to implement it.

Increasing employee engagement around the topic of circular economy required a multi-pronged approach that included:

Storytelling to bring life to the circular economy concept to different audiences

Building communities and creating dedicated hubs for different departments and regions to connect to knowledge and experts

Dedicated training for priority audiences

Embedding best practices and learning from pilots into the key processes, such as strategic roadmaps and design guidelines

Philips’ product and service architects are an example of a priority group. Training of this group meant expanding the concept of design beyond just costs and performance, to include criteria such as energy efficiency, modularity, upgradability, substance and material use and reusereuseThe repeated use of a product or component for its intended purpose without significant modification. — in other words, designing with the whole system in mind. These ‘Ecodesign criteria’ have been fully embedded into Philips’ ways of working and include specific ‘circular ready’ design requirements for individual product categories.

To support internal capacity building across the organisation, a circular community of practice was established, with experts, cases, and learning from across businesses, functions and markets, to ensure that the circular economy is integral at every stage of the value chain.